Our expert team masters every production stage of complex pieces. The process includes planning and setting-up the pieces using high-precision machine settings before production starts, then milling and thoroughly checking each piece before delivery.

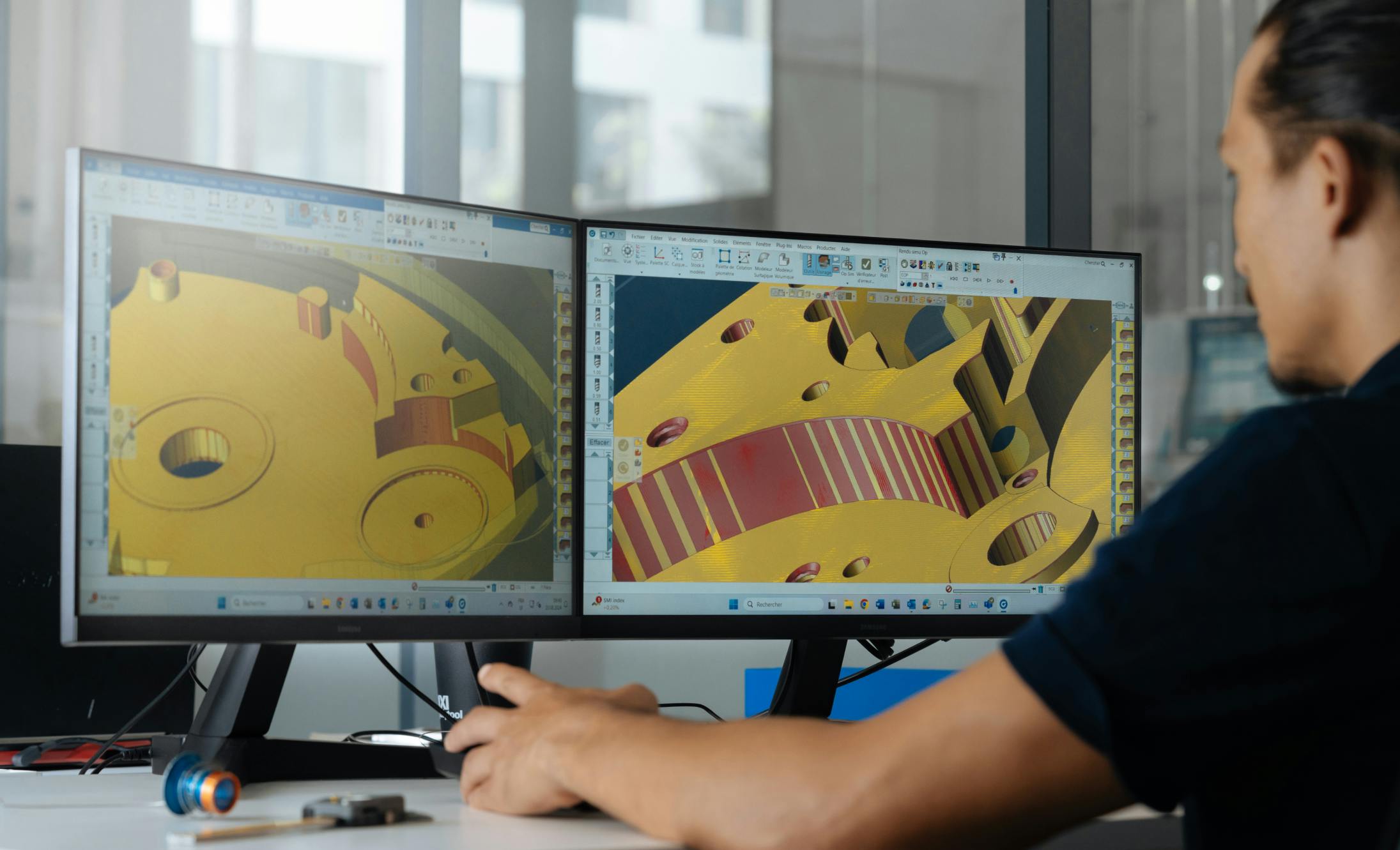

CNC programmers

Our programmers carefully study the drawings of the components to be machined in order to design, correct or improve the computer programming of CNC or 3D machines.

They plan and analyse the sequence of operations and machine movements in detail, and precisely code the machining process to manufacture parts identical to the initial design.

Microengineers

Our experts draw up plans, sketches and manufacturing documents for very small watch components (movement parts, gear trains, etc.)as well as for the associated measuring or control instruments. Very meticulous and precise in their work, our micro-engineers process individual components, such as gear trains and springs, on request. They program computer numerical control machines (CNC), carry out the manufacturing and check the conformity of the machined components. They produce unique pieces, prototypes or limited series according to customers’ wishes and requirements.

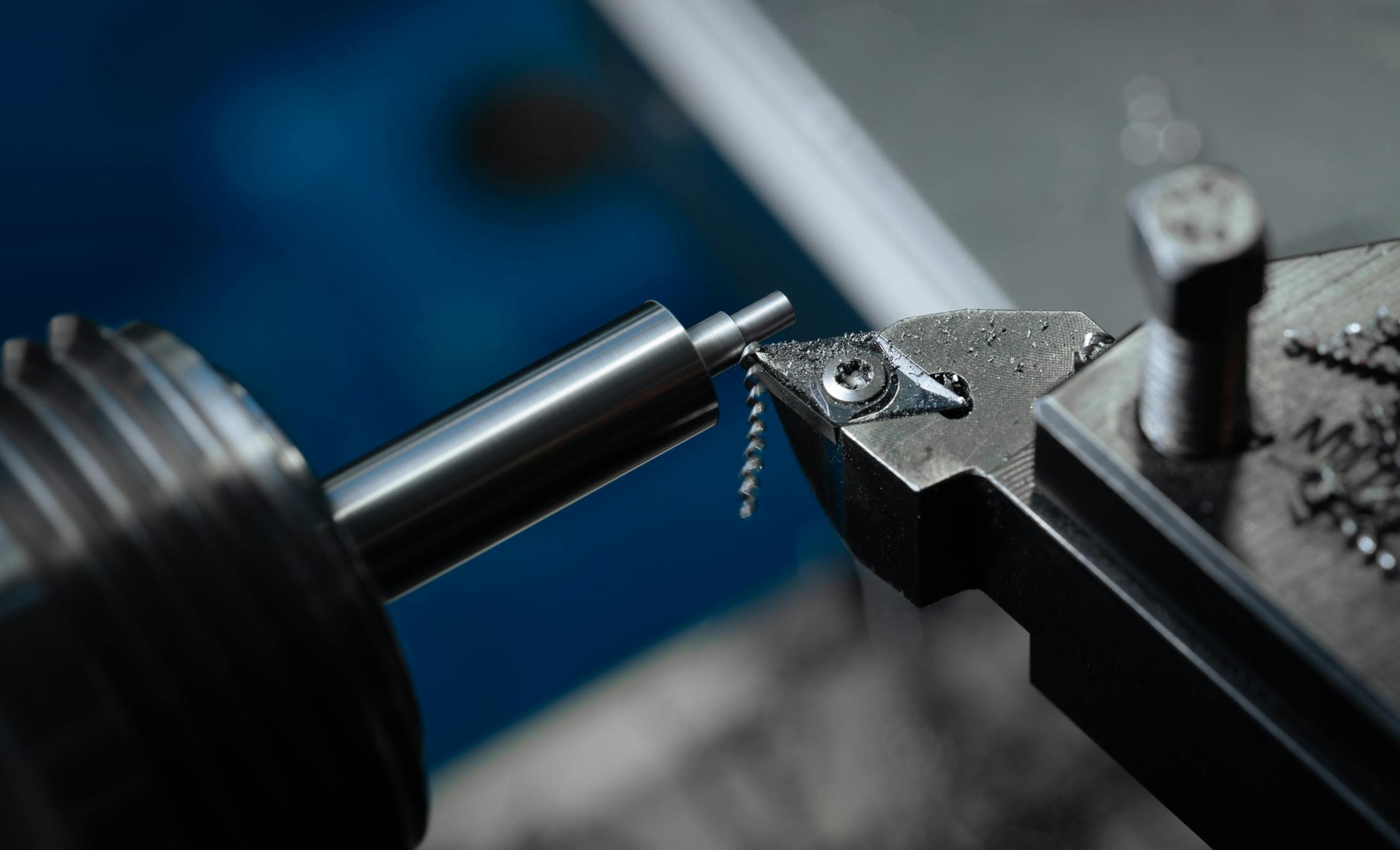

Specialising in the manufacture of monobloc gongs

Specialising in high-precision watchmaking, the craftsman processes the gong as a single block, a long-standing artisanal practice. This key component of chiming watches can be composed of one or two strands. Varying in shape and complexity, it can also be used in all kinds of chiming watches: equipped with a minute repeater, an alarm, an hourly chime...

The distinct "Monobloc" characteristic of the gong ensures optimal sound propagation, guaranteeing exceptional sound quality.The precision of its shape improves the adjustment within the watch mechanism, thus simplifying the assembly process with fewer manual reworkings. For the watchmaker, this results in precious time savings when setting the chimes.

ADVANTAGES OF A MONOBLOC GONG:

- Optimal sound propagation

- Consistent frequency between the hammers

- Better aging

- Exact shape

- Less manual finishing

- Time-saving for the watchmaker

- Homogeneous and defect-free wire

- Easier tuning

- Constant hardness

Preparation for setting

The craft of setting preparation involves preparing the components of a watch or jewelry piece before the insertion of gemstones. This includes marking and drilling the locations for the stones, adjusting the settings to ensure precise mounting, while adhering to high standards of quality and aesthetics. Close collaboration between the setter and the preparer ensures that each stone fits perfectly into the final design.

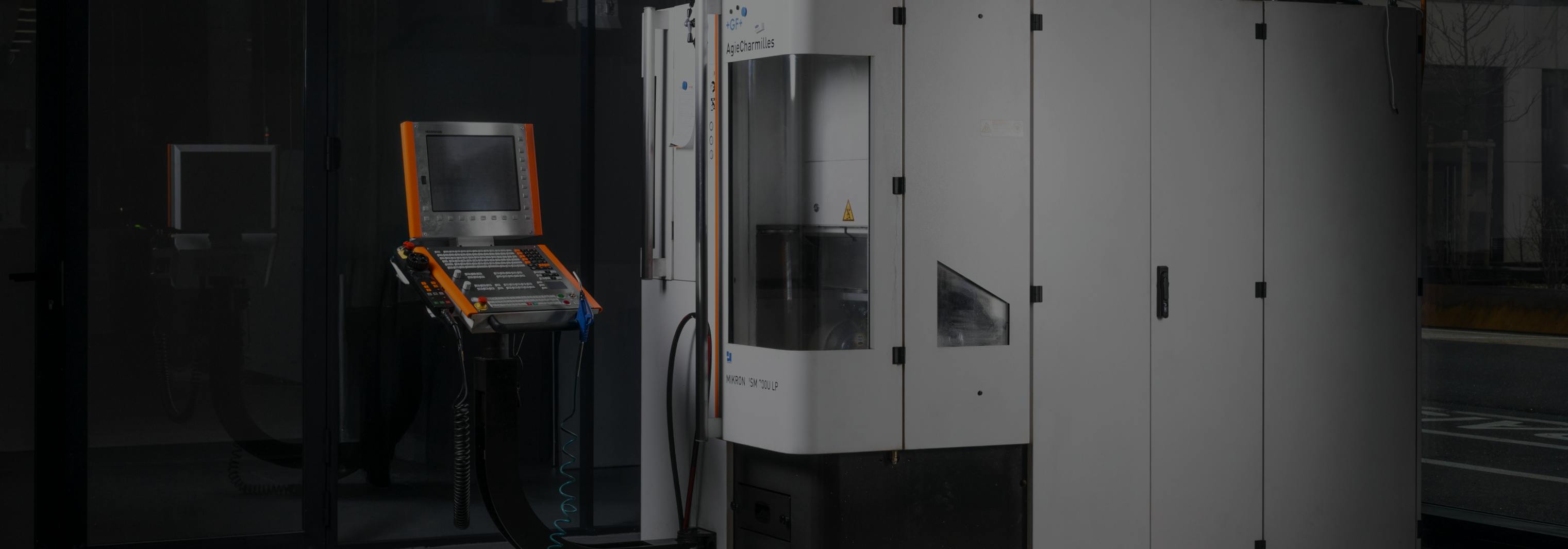

Flexible and responsive, Manufacture Horlogère Genevoise is able to respond rapidly to the most varied requests, whether for conventional milling work, 3-axis or 5-axis CNC machining.